Industrial Coffee Grinder: Finding the Perfect One for Your Business

Industrial Coffee Grinder: Finding the Perfect One for Your Business

Blog Article

Industrial Coffee Mill Guide: Increase Performance and Top Quality

In the competitive landscape of coffee manufacturing, selecting the ideal commercial coffee grinder plays a critical duty in enhancing both effectiveness and item high quality. Comprehending the nuances of numerous mill types and key functions-- such as customizable grind setups and robust building-- can significantly influence the last taste profile of the coffee. The optimization of the grinding procedure, combined with attentive upkeep, is important for sustaining efficiency over time. As we discover these crucial aspects, it ends up being obvious that the effects extend beyond simple devices option, impacting overall business success in methods that require closer examination.

Understanding Grinder Types

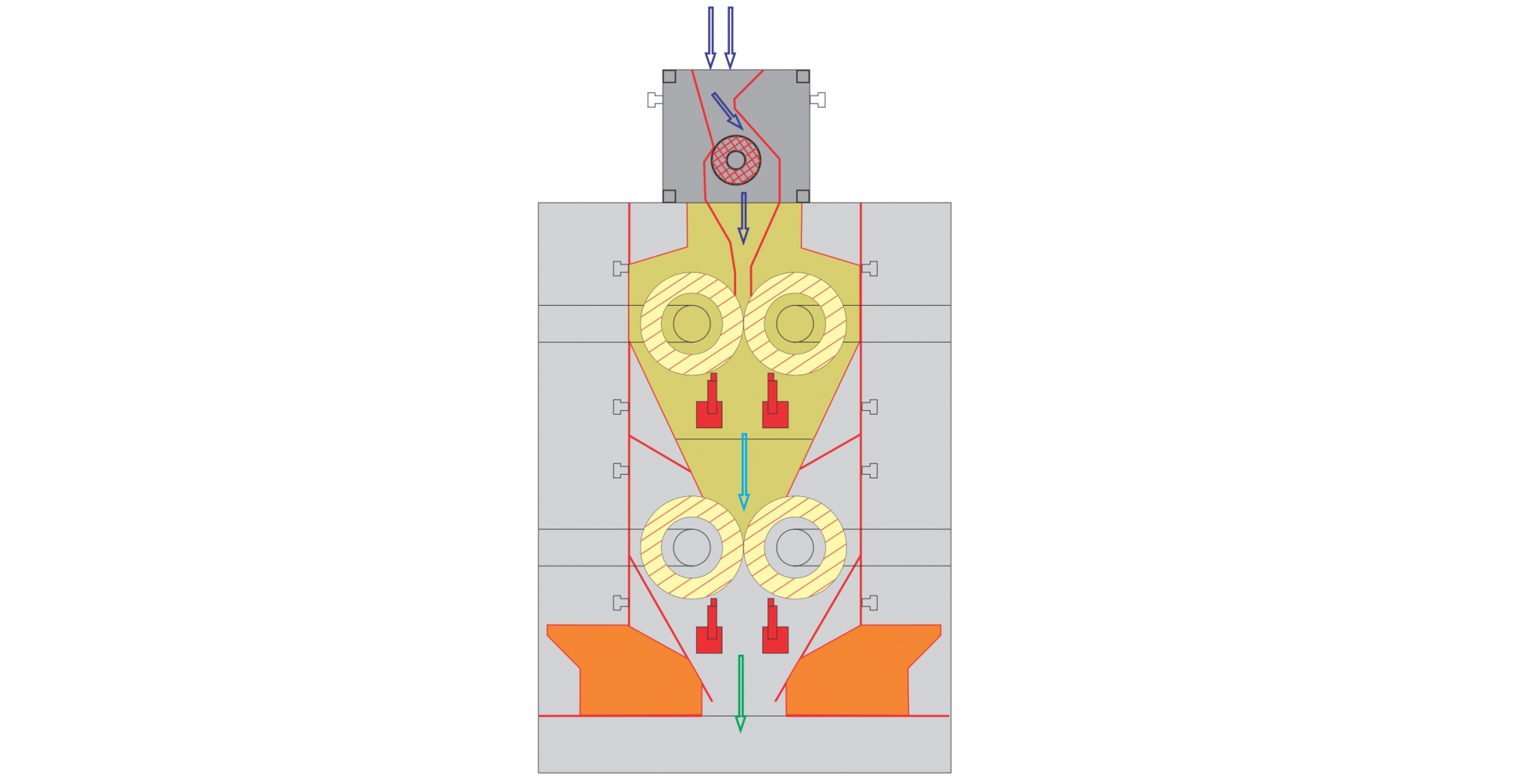

When selecting an industrial coffee mill, understanding the various kinds offered is crucial for optimizing both flavor removal and functional efficiency. The 2 main sorts of mills are blade grinders and burr grinders. Blade grinders make use of sharp blades that slice coffee beans into inconsistent sizes, leading to irregular removal and potentially unwanted flavors. While blade mills are often more inexpensive and suitable for small operations, they are normally not advised for commercial use.

Eventually, choosing the appropriate sort of mill is integral to preserving high quality and effectiveness in coffee manufacturing, making it critical for companies to spend in high-grade burr grinders for optimum outcomes.

Key Attributes to Take Into Consideration

Choosing a commercial coffee mill requires careful consideration of a number of vital features that can substantially affect both efficiency and the overall coffee experience. One of the key facets to assess is the grinding system. Burr mills are typically chosen over blade mills, as they supply a constant work dimension, which is essential for ideal extraction and taste.

An additional essential feature is the grinder's capacity. Relying on the quantity of coffee you need to process, choose a model that can handle your demands without sacrificing speed or quality. In addition, consider the work setups supplied. A functional mill with several settings permits you to customize the work dimension to various developing approaches, boosting the coffee's taste account.

The building and construction material additionally contributes in durability and upkeep. Stainless-steel parts usually use durability and are easier to cleanse, which is necessary for maintaining health criteria. Last but not least, review the mill's noise degree, specifically in a hectic café or production environment, where excessive sound can be disruptive. Buying a grinder that stabilizes these features can greatly improve both functional effectiveness and the quality of the coffee served.

Optimizing Grinding Process

To attain the very best lead to coffee preparation, enhancing the grinding procedure is necessary. The grind size significantly next influences removal, taste, and overall high quality of the made coffee. Various developing methods require certain hop over to these guys work dimensions; as an example, espresso demands a fine work, while French press requires a rugged texture. Comprehending the connection in between work dimension and developing method is the very first step in optimization.

In addition, keeping an eye on the grinding rate can maximize the procedure. Slower grinding usually creates less heat, maintaining fragile flavors and scents. Alternatively, quicker grinding may generate too much warmth, negatively impacting the coffee's top quality.

Upkeep and Treatment Tips

Appropriate maintenance and treatment of commercial coffee mills are vital for making sure optimal performance and durability. Routine cleansing is the structure of upkeep; residue buildup can affect taste and grinding performance. It is a good idea to clean up the grinder after each use, wiping down the outside and getting rid of any type of coffee grounds from the burrs.

Additionally, check the grinding burrs for wear and tear. Dull burrs can compromise work consistency, so they must be changed as essential. Industrial Coffee Grinder. Periodically adjusting the grinder is also important, as this preserves the wanted grind dimension for different brewing approaches

Lubrication link of relocating parts must be performed according to the producer's requirements, as this decreases rubbing and extends the life of the tools. It is necessary to make use of food-grade lubricants to guarantee security and conformity with wellness guidelines.

Last but not least, maintain the grinder in a completely dry and steady environment to protect against corrosion and corrosion. By adhering to these upkeep and treatment pointers, drivers can improve the efficiency of their commercial coffee grinders while making certain high-quality result and prolonged operational life.

Return on Investment Evaluation

Assessing the roi (ROI) for commercial coffee grinders is essential for organizations seeking to optimize their coffee production abilities. A comprehensive ROI analysis assists establish the economic viability of buying high-grade mills, permitting companies to consider the initial costs versus prospective gains.

Examine the acquisition price of the grinder, including installation and any type of needed alterations to existing facilities. High-performance grinders commonly lead to lowered grinding time and raised throughput, which can considerably enhance performance.

Additionally, consider the influence on product high quality. Industrial Coffee Grinder. Superior grinders yield an even more consistent grind dimension, which can enhance taste profiles and consumer satisfaction, eventually driving sales. By enhancing the high quality of the last product, organizations can justify higher prices, leading to enhanced profits

Verdict

In recap, an industrial coffee mill plays a crucial role in boosting both performance and product top quality within coffee manufacturing. Inevitably, the tactical financial investment in a trusted mill contributes dramatically to enhanced earnings and competitiveness in the coffee market.

In the affordable landscape of coffee manufacturing, choosing the right industrial coffee grinder plays a critical function in boosting both effectiveness and product quality. The two key kinds of mills are blade grinders and burr grinders. Within the burr grinder group, there are flat burr mills and conical burr mills, each with its advantages. Burr grinders are usually preferred over blade mills, as they give a constant work dimension, which is critical for optimal removal and taste.

In recap, a commercial coffee mill plays a pivotal function in improving both effectiveness and product quality within coffee manufacturing.

Report this page